Drill Bit Selection

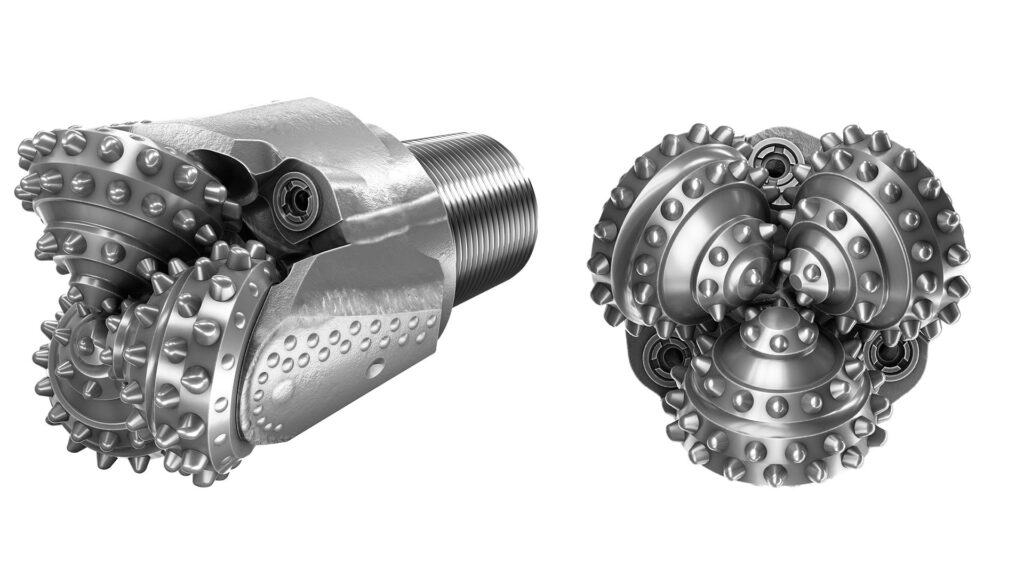

Published — 2022-05-09With many choices available today, selecting the proper bit for a particular application can be quite confusing. Choices include spade, drag and shear type bits, point attack bits, PDC bits (polycrystalline diamond compact), Milled Tooth and TCI (tungsten carbide insert) roller cone bits.

There are IADC codes (International Association of Drilling Contractors), soft, medium, and hard categories for each bit, sealed, non-sealed, roller, and friction bearings. The list goes on. What is a contractor to do when the success of the drilling operation is directly related to what is attached on the end of the drill pipe?

In an effort to simplify the process, we suggest a simple, systematic approach. This process involves a few simple steps:

- Identify – Soil / Rock Type(s)

- Classify – the Soil / Rock Category

- Choose – a bit type within the category

- Optimize and adjust – operating parameters/ subsequent selection.

Identify

Obtain geotechnical information. This part of the process is the most important. When done correctly, it will ensure proper tool selection and application through reaming.

On larger pipeline jobs, owners often supply contractors with accurate formation properties including rock compressive strengths. However, in many cases where detailed information is not provided, we suggest the following:

Perform a site survey. Sometimes actual geology is exposed from pre-existing road work, other construction, or through on-site pot holing.

- Contact the relevant authorities for geology specific to a location.

- Contact the relevant authorities for soil surveys in a specific area.

- Contact local water well drillers.

- Contact local construction companies.

- Contact tooling suppliers/ manufacturers, they may provide information related to past experiences in specific areas.

Remember, you are interested in the geology that exists within 100 ft. (or less) of the surface. The more information you obtain the better equipped you’ll be to make the right choice.

Classify

Define Soil / Rock Category:

| Compressive Strength | Hardness Range Soil & Rock Types |

| 0 to 2,500 PSI / Low | Dirt, Clay, Cobble, Talc, Shale, Siltstone |

| 2,500 to 7,000 PSI | Unconsolidated Sandstone, Shale, Limestone |

| 7,000 to 15,000 PSI | Consolidated Sandstone, Shale, Limestone |

| 15,000 to 25,000 PSI | Harder formation Sandstone, Shale, Limestone, Dolomite |

| 25,000 PSI + | High Finely Grained Granites, Trap Rock, Chert, Iron formations, Quartzite. |

Bit Selection

Choose a bit within the category. Bit choices progress from softer to harder in descending order.

Choices listed within each category should produce cost-effective results. However, there can be overlap between hardness categories. The use of a downhole motor can influence bit choice. Blade and point attack type bits are commonly used without a downhole motor.

| Compressive Strength | Hardness Range Soil & Rock Types |

| 0 to 2,500 PSI / Low | Low Drag or Blade Type (duckbill, spade, etc.) |

| 2,500 to 7,000 PSI | Point Attack, Shear Type (PDC) Milled Tooth & Aggressive TCI Roller Cone |

| 7,000 to 15,000 PSI | Shear Type (PDC) Aggressive to Medium Formation TCI Roller Cone |

| 15,000 to 25,000 PSI | Medium Formation TCI Roller Cone with Chisel or Round Top Inserts |

| 25,000 PSI + | Hard Formation TCI Roller Cone with Domed Inserts |

Optimize

Utilize and adjust the subsequent selection, if required:

- Talk to suppliers and manufacturers of these products. They can provide recommended operating parameters and guidelines for optimal use.

- Noting and identifying cuttings return characteristics, while drilling, can help in refining ongoing utilization and selection.

Other General Considerations

- Rig operating limits can influence bit selection.

- Torque requirements become greater in softer materials.

- The weight on bit (WOB) requirements become greater in harder materials.

- Sealed, friction bearing, roller cone bits are preferred for fluid applications. However, open bearing roller cone bits are used successfully on shorter bores of less than 200 feet.

- TCI roller cone bits (TCI – tungsten carbide inserts) with round top shaped inserts will produce the slowest rate of penetration (ROP).

- Maximum gage, shirttail, and leg protection will increase bearing life and drilling hours of the roller cone bit.

- Your rig operating cost investment outweighs the cost of a drill bit. Choose a bit that produces the most cost-effective balance of ROP and total run time, as trip time is costly. Improved ROP means less drilling hours, and money saved.

- Conventional “petroleum” roller cone bits are not always best suited for HDD. Certain bits, designed specifically for HDD, can prove to be more cost effective.

- Re-run roller cone bits are “used bits”. No one can tell you “how used” they are. They are considered a risk and discarded by petroleum operators. Consider the investment in your bore and weigh the risks.