Importance of reamer centralization in HDD

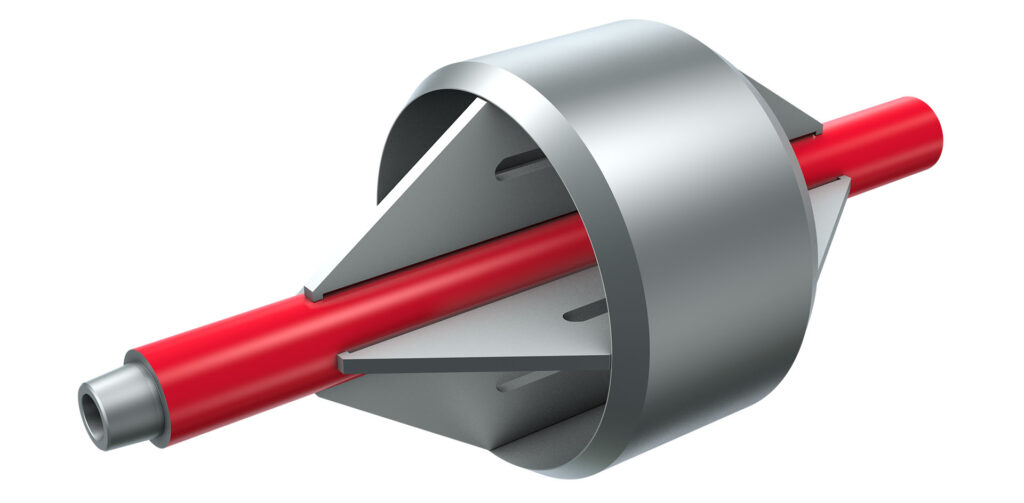

Published — 2022-04-05Centralizers are one of the most important but often overlooked tools in an HDD bottom hole assembly. Its primary function is to keep the reamer correctly positioned within the bore to maximize life and ensure proper bore hole geometry. Centralizers can contribute strongly to a lower overall cost per foot of drilling and increase the odds of a successful HDD project.

An un-centralized reamer poses a risk in your HDD operations. Without centralization, a hole opener will violently bounce from side to side of the bore. This movement puts tremendous impact force on the tool which can lead to premature damage or weakening of various components. The tool body will sustain high impact forces, which weakens both the steel and the weld integrity over time, potentially leading to body failure.

In addition, the slamming of the reamer into the bore will keep the cutters from being evenly and properly loaded, which leads to premature failure. Common side effects include broken inserts, worn or broken milled tooth teeth and early bearing or seal failures. The best possible outcome of improper centralization is that drilling rate of penetration and reamer life will be dramatically reduced. The worst possible outcome of improper centralization could be catastrophic tool failure, resulting in leaving parts downhole and potential loss of the hole. The good news is that centralization is relatively easy to implement and generally one of the least costly components of the bottom hole assembly. Centralization can take the form of a separate tool or be built into the reamer itself. Generally, centralization should be 1.5” to 2” under the gauge of the reamer. There are many ways to build a centralization plan and contractors should consult their tooling partners to develop an optimal strategy. Overall, centralization is critical to achieving maximum life out of HDD reamers as well as ensuring proper bore hole geometry.