What does differential pressure have to do with effective mud motor drilling?

Published — 2022-04-25Differential pressure is the key to drilling with a mud motor. Knowing your off-bottom pressure, on-bottom pressure and stall point will increase your rates of penetration and ensure maximum drilling hours with the motor.

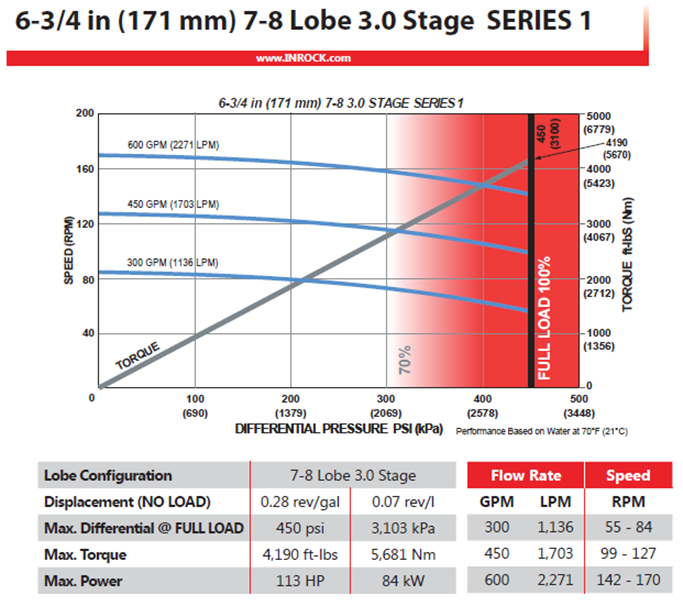

All mud motors have a flow range based on the power section. The motor will run most effectively on the upper end (70% to 85% of maximum flow capacity) of the power section. The motor specification sheet will provide the bit speed, rotary torque and differential pressure based on the flow rates of the power section:

The motor produces higher bit speeds, higher rotary torque and allows for higher differential pressures on the upper end of the power section. The higher rotary torque and higher bit speeds will help maximize rates of penetration and keep the motor from stalling out. If flow rates are too low, the motor produces lower bit speeds, less rotary torque and less differential pressure allowing the motor to stall out easily.

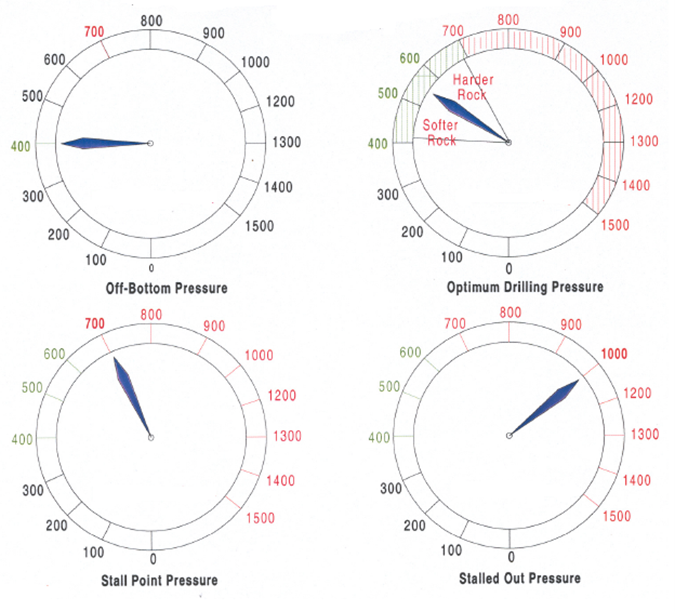

Mud pressures should be monitored on the rig’s mud pressure gauge:

Off-bottom Pressure

- The pressure registered on the mud pressure gauge when the mud pump in engaged.

- The pump should be working at the speed that will be used to drill the formation.

- Check the off-bottom pressure periodically as it will increase as more drill pipe is added to the drill string.

Stall Point Pressure

- The exact point on the mud pressure gauge that the motor becomes overpowered.

which causes the drill bit and internal movement of the power section to stop working.

Stalled Out Pressure

- An immediate jump of 300 PSI or more after reaching the stall point.

- Pull the motor off-bottom immediately to prevent motor damage. The mud pressure will then fall to the off-bottom mud pressure point.

Optimum Drilling Pressure

- The point that allows for maximum rate of penetration while working the motor at the easiest differential pressure.

- The optimum drilling point will depend on rock type, rock hardness, volume requirements of the motor and hydraulic horsepower of the mud coming out of the nozzles in the drill bit.

The mud motor runs most effectively and maximizes rates of penetration just below the stall point.